yaotai fileEven though the China machine manufacturing market is expected to continue expanding quickly, selecting the ideal strategic partner for your CNC machining might be difficult. However, if you have the right bits of advise beforehand, this approach shouldn’t be too challenging. The following machine shop recommendations may be useful to you as you search for the best service provider.

1: The Technology in Use

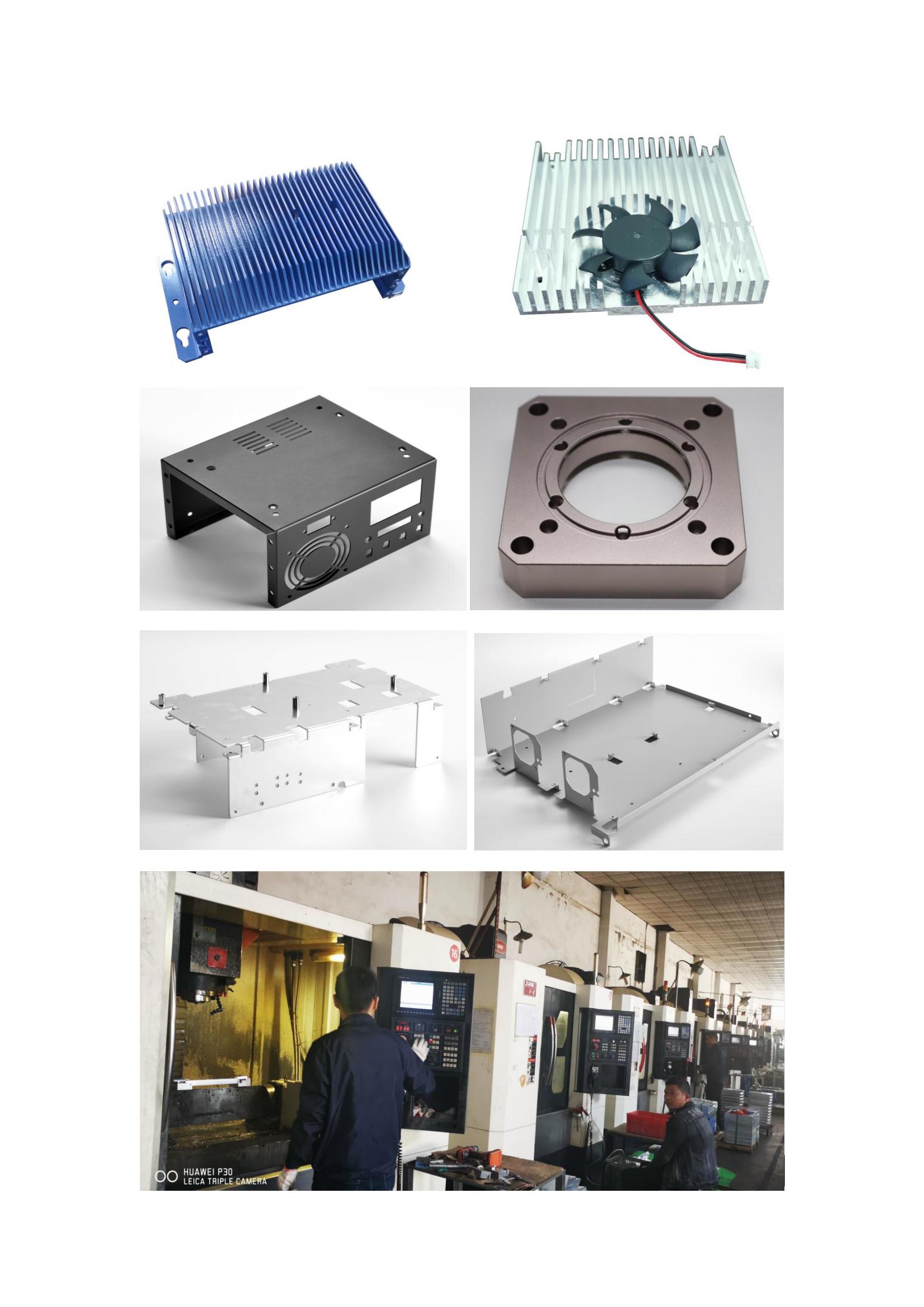

In the field of engineering and production, technology has tremendous power. Knowing the kind of technology being used in your selected machine shop is thus a great idea. Despite the fact that many businesses rely on standard technology, this could be a limitation in terms of design and machining. Working with a manufacturer who is completely automated and outfitted with all essential precision tools and machinery is therefore essential. At Yaotai Team, we have made significant investments in CNC manufacturing, which enables us to provide our customers with precision component machining.Additionally, this ground-breaking manufacturing strategy aids us in achieving zero-defects because our CNC machines can repeatedly run the production process after receiving your design from the computer. Additionally, this cuts down on lead times.

2.The staff’s level of expertise

Sometimes you could choose a pricing that seems reasonable just to receive a component that doesn’t match your print or assembly. In other instances, the manufacturer may tell you that the reason for the delay is that “your component design is too complex.” Therefore, you must exercise caution when working with machine shops and only choose a business that has a track record of correctly interpreting designs and prints and completing projects on schedule. Our machinists may build a long-term career at Yaotai Team. We are well aware that even the most costly hardware and software will be useless without a team of skilled workers who can provide the highest caliber services and adhere to the most exacting client requirements. As a matter of fact, the vast majority of our machinists are graduates of China manufacturing institutions and are capable of handling any complexity connected to the design and implementation of components.

3. Relationship Sustainability

If you’re thinking about signing an Original Equipment Manufacturer (OEM) contract with a CNC machining company, you may want to examine how long the partnership will last. Consider whether the company has the necessary CNC automation to satisfy your demand and demands first. Second, the machine shop with which you wish to enter into a contract must safeguard your company interests and take end-user needs into account. Having stated that, Yaotai Team is well known for producing parts for EOMs in practically every industry. With a production capability of around 50,000 components per year, we can meet your demand without sacrificing quality. Additionally, we safeguard the interests of our clients by keeping our connections with EOMs that purchase our components a secret.

Post time: May-12-2023