Here at Yaotai, we offer several different finishing options in order to suit your specific needs and desired aesthetics:

Bare metal finishes

No Finish is when the part comes out of the machine “as is”. This means it will have visible tool marks and scratches. No finish parts have no additional cost, which gives them the best economics for functional parts that will not be displayed.

No Finish parts can also be considered “stock finish”, if the part’s exterior isn’t touched by the tooling during the turning process. If that’s the case, the parts may have stickers, stamps or other material identification from the material vendor.

Anodizing:It is typically used on machined aluminum parts to reduce corrosion and add an appealing metallic coloring. Anodizing is a scratch-resistant coating that is both a natural electrical insulator and one of the most durable finishes.

Brushing Used on metals where a series of tiny parallel lines are scratched onto the surface with a wire brush or polishing tool

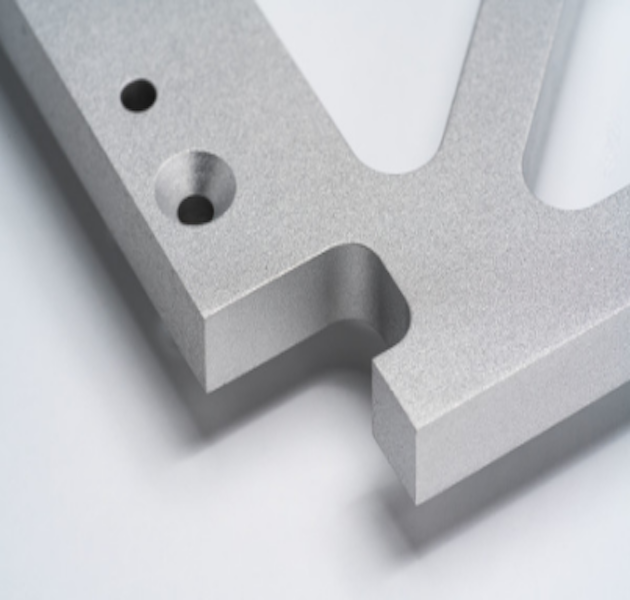

Bead Blasting is another bare metal finish option offered by Yaotai. Bead blasting is applied by spraying a steady stream of tiny glass beads via compressed air. The end result is a flat, non-directional finish that provides excellent aesthetics.

Powder coating is the standard finishing option of painting metal. Our team applies powder coat by spraying a dry, free-flowing powder across your metal parts in order to impart a finish that is durable, high-quality and available in a variety of colors. Check out our powder coating page for full details on the powder coat colors and textures we offer.

Polishing Get smooth surface by removing cutting marks or printing marks. It is prepare your parts for later painting and plating. For a variety of metallic effects, we can provide brushed and satin surfaces, as well as optically clear polishes on transparent acrylics.

Conclusion

For parts that have an overall cylindrical geometry, CNC turning is the logical means for creating those parts. This guide has covered all of the basic information about CNC turning, including our manufacturing guidelines for CNC turned parts.

In the end, Yaotai is here to make your custom parts – whether sheet metal, CNC turned, CNC milled and 3D printed – in the exact quantity you require, within our ultra-fast lead times so that you can keep your project moving.

Got a design in mind? You can contact us to get connected with your Yaotai Account Manager, or use our Request-A-Quote form to submit your design for quoting.

Post time: May-07-2022