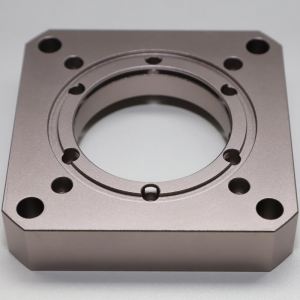

CNC Machining Aluminum Face Recognition Machine Frame

One of the great advantages of CNC machining is its versatility. That’s because precision CNC milling and turning works successfully using a very wide variety of raw materials to produce finished parts. This gives design engineers many options when it comes to creating prototypes and commercial products.

Although many types of metal and plastic can by formed with CNC machining, it’s essential to understand their different properties if you want to get the best results to suit your application. To help make your choice easier, we’d like to talk about the most common materials that we use everyday for the majority of products that we make.

Aluminum 6061:6061 is a widely used materials in various industries. Aluminum are used for auto parts, bicycle frames, sporting goods, some aircraft components and frames for RC vehicles.

Aluminum 7075:7075 is a higher grade of aluminum.It’s one of the strongest aluminum alloys used in machining, with excellent strength-to-weight characteristics.It’s used for high-strength recreational equipment for mountain climbing, as well as for automotive and aerospace frames and other stressed parts.

Brass:Brass is common in plumbing fittings, home decorative hardware, zippers, naval hardware and musical instruments.

Magnesium:Magnesium is often used for aircraft components in which light weight and high strength are most desirable, and can also be found in the housings for power tools, laptop cases and camera bodies.

Stainless Steel 303: 303 is often used for stainless nuts and bolts, fitting, shafts and gears. It should not, however, be used for marine grade fittings.

Stainless Steel 304:304 is an excellent material choice for kitchen accessories and cutlery, tanks and pipes used in industry, architecture, and automotive trim.

Stainless Steel 316:316 is used in architectural and marine fittings, for industrial pipes and tanks, automotive trim and kitchen cutlery.

Titanium:Titanium is well-known for possessing high strength, light weight, toughness and corrosion resistance. It is used in aerospace, military,bio-medical land industrial fields