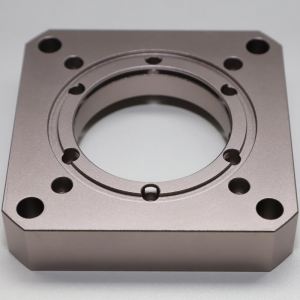

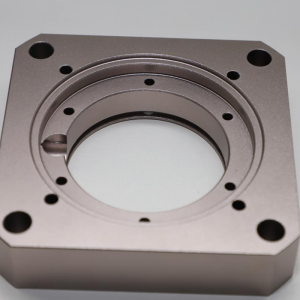

CNC Machining Machined Anodized Aluminium Parts

In an effort to greatest meet client’s requires, all of our operations are strictly performed in line with our motto “High Excellent, Aggressive Selling price, Fast Service” for Factory supplied Factory Precision Custom Milling Turning CNC Machining Machined Anodized Aluminium Parts, Welcome to visit us at any time for organization marriage established.

In an effort to greatest meet client’s requires, all of our operations are strictly performed in line with our motto “High Excellent, Aggressive Selling price, Fast Service” for China CNC Machining Part Aluminium and CNC Turning Aluminium, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we are going to continue to develop, to supply the high-quality merchandise and services, and promote lasting cooperation with our customers, common development and create a better future.

1.Materials: Aluminum, also can be any that you want.

2.Surface treatment: anodizing and sandblasting, as what you want.

3.Process: CNC machining and drilling

4. Inspection machines: CMM, 2.5D projector to assure the quality requirements.

5. Compliant with RoHS Directive.

6. Edges and holes deburred, surfaces free of scratches.

7. We accept any OEM orders and can accept small orders for test quality.

MOQ: ≥1 piece or according to customer’s request

Payment: 50% deposit, 50% balance in advance

Delivery Time: 2-3weeks

FOB Port: Shenzhen port

Quality Control: 100% inspected

CNC (Computer Numerical Control) machining is a subtractive manufacturing technique: parts are made by removing material from a solid block (called a blank or blank) using a variety of cutters.

It is a fundamentally different type of manufacturing than additive (3D printing) or molding (injection molding) technologies. Material removal mechanisms significantly affect CNC strengths, limitations, and design limitations. Read more below.

The basic CNC process can be divided into three steps. We engineers start by designing a CAD model of the part. The machinist then converts the CAD file into CNC software (G-code) and sets up the machine. Finally, the CNC machining system does everything to remove the material and manufacture the parts with little supervision.

Below are just several common surface treatments that we have used for our products, if you need any others please contact us. We will review your requests and feedback to you.

Anodizing: anodizing is frequently mentioned, it is a process that converts the surface of a non-ferrous metal into a corrosion-resistant, decorative, non-conductive oxide. Varies kinds of colors can be chosen.

Sandblasting:sometimes known as abrasive blasting, is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants

Polishing ![]() olishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment, leaving a clean surface with a significant reflection specular.

olishing is the process of creating a smooth and shiny surface by rubbing it or by applying a chemical treatment, leaving a clean surface with a significant reflection specular.

In an effort to greatest meet clients’ requirements, all of our operations are strictly performed in line with our motto “High Excellent, Aggressive Selling price, Fast Service” for Factory supplied Dongguan Factory Precision Custom Milling Turning CNC Machining Machined Anodized Aluminium Parts, Welcome to visit us at any time for organization marriage established.

Factory supplied China CNC Machining Part Aluminium and CNC Turning Aluminium, Our company offers the full range from pre-sales to after-sales service, from product development to audit the use of maintenance, based on strong technical strength, superior product performance, reasonable prices and perfect service, we are going to continue to develop, to supply the high-quality merchandise and services, and promote lasting cooperation with our customers, common development and create a better future.