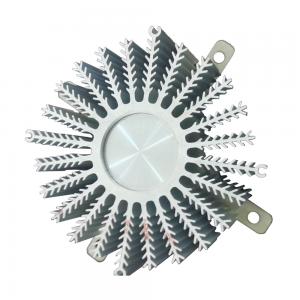

Competitive Price for Custom Radiator Heat Sink Aluminum Extruded Anodized Enclosure Profile Heat Sink for CNC Machining / Car / Electric Vehicle /Computer

Bear “Customer first, Quality first” in mind, we work closely with our customers and provide them with efficient and professional services for Competitive Price for Custom Radiator Heat Sink Aluminum Extruded Anodized Enclosure Profile Heat Sink for CNC Machining / Car / Electric Vehicle /Computer, should you’ve any query or wish to place an initial buy make sure you will not wait to get hold of us.

Bear “Customer first, Quality first” in mind, we work closely with our customers and provide them with efficient and professional services for China Skived Fin and Aluminium Profile, You can allow us to know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will provide our best service to satisfy all your needs! Make sure you contact us right away!

Depending on the shape and material, heat sinks can be made using a variety of manufacturing methods. The most common and inexpensive methods include extrusion, forging, casting, and stamping. Other costly methods include CNC machining, turning and forging. Like our product: Aluminum CNC machined and extruded heat sink for cooling. This one is produced by extrusion and CNC machined processes, which can make the cost much better.

Extrusion is the most cost-effective process for manufacturing finned heat sinks. But further secondary operations add to the overall cost.

Cold forging is a highly precise process that can produce round and oval pin radiators. Due to the high pressure and low temperature, forged heat sinks have very good micro structural integrity.

Casting, especially die casting, can produce heat sinks with complex geometries. But the materials that can be cast have lower thermal conductivity than those used in extrusion and forging.

Stamping is often used to make tall heatsinks that require heat pipes to pass through the fins.

Turning and swaging can be used to manufacture special radiators. But because they are expensive, they are only used in applications where cost is not a sensitive factor.

CNC machining is a versatile manufacturing method that can produce radiators with the most complex geometries or parts that require urgent deliveries, but cost is often a disadvantage.

No matter what you want, contact us and we will offer the best solution with affordable prices to you.

Bear “Customer first, Quality first” in mind, we work closely with our customers and provide them with efficient and professional services for Competitive Price for Custom Radiator Heat Sink Aluminum Extruded Anodized Enclosure Profile Heat Sink for CNC Machining / Car / Electric Vehicle /Computer, should you’ve any query or wish to place an initial buy make sure you will not wait to get hold of us.

Competitive Price for China Skived Fin and Aluminium Profile, You can allow us to know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will provide our best service to satisfy all your needs! Make sure you contact us right away!