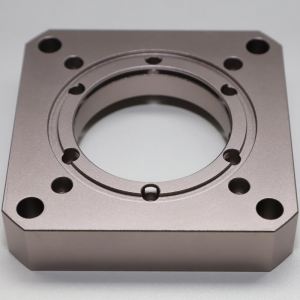

Precision Aluminum Custom Metal Stamping Parts

The sheet metal, die, and press machine are the only real three parts in sheet metal stamping, albeit each part may go through several processes to reach its final shape. The instruction that follows covers a few typical procedures that could happen while metal stamping.

Forming: The process of forcing flat metal into a different shape is referred to as "forming." Depending on the design requirements for the part, it can be done in a variety of methods. The metal can be transformed from a very simple shape to a complicated one by a succession of processes.

Blanking: The simplest process is known as "blanking," which begins when the sheet or blank is inserted into the press and the die is used to cut out the desired shape. The finished product is known as a blank. The blank may be a fully finished blank, which is the intended part, or it may proceed to the next step of forming.

Piercing: With piercing, which is nearly the reverse of blanking, technicians use the material on the outside of the punctured region rather than keeping the blanks. Consider cutting biscuits from a rolled-out dough circle as an illustration. The biscuits are saved during blanking; however, when piercing, the biscuits are thrown away and the hole-filled leftovers constitute the desired result.

Drawing: Drawing is a more difficult procedure that creates vessels or significant depressions. To modify the shape of the material, tension is utilized to precisely drag it into a cavity. Although the material may expand while being drawn, experts work to minimize stretching in order to preserve the integrity of the material. Drawing is typically used to make oil pans, cooking utensils, and sinks for vehicles.

Even while almost any metal, even gold, can be stamped, sheet metal is the most typical type. The required type of part and desirable attributes, such as corrosion- and heat-resistance, determine the type of metal that is utilized.

The following materials can be used to make parts using sheet metal stamping:

●Brass

●Low- and high-carbon steel

●Copper

●Aluminum

●Titanium

●Stainless steel

●Nickel alloys

●Bronze

●Inconel

With the aid of highly specialized computer-aided drawing and production applications, sheet metal is molded into intricate pieces during the stamping process. Stamping sheet metal rapidly and effectively produces outstanding, durable, heavy-duty products. Results are usually more dependable and constant than hand machining because of how accurate they are.

Sheet metal stamping-produced components are used in the following sectors:

●Renewable energy

●Automotive

●Industrial

●Hardware

●Medical

●Home Improvement